Products

Palm EFB Pellet Line 2000KG

What are EFB pellets?

EFB Pellets originates from the residue of the empty fruit bunches of the oil palm trees. They are processed without

chemicals and environmentally friendly. It is GREEN ENERGY.

GREEN ENERGY = HEALTHY LIVES

|

Why use EFB(Empty fruit bunch) to make pellets?

Palm oil mill EFB (Empty fruit bunch) accounting for about 22-23% of the fresh fruit bunch (FFB) processed. A palm

At the same time, the rapid depletion of fossil fuel needs an alternative replacement, biomass fuel such as wood or

The pioneers from Malaysia and China have set up several EFB pellet lines in Malaysia, consumers are the biomass

power plants from South Korea and Japan.

How to turn EFB(Empty fruit bunches) into Pellets?

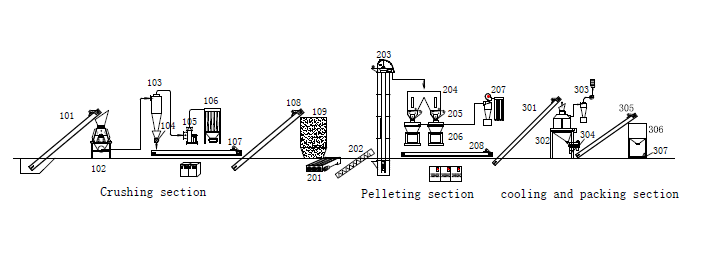

Processing of empty fruit bunch to pellets involves the basic processes, such as the size reduction of the bunches to

fiber, fiber drying, fiber to pellet compressing, followed by pellets cooling and separating process after pellets being

produced

|

Therefore, the EFB Pellet Plant will be made of EFB Chipper, Rotary drum Dryer, EFB Fiber miller, EFB Pellet Mill,

Cooler, Pellets Separator, EFB pellets Packing Machine, and auxiliary equipment like conveyors.

Main Machine in the EFB Pellet plant

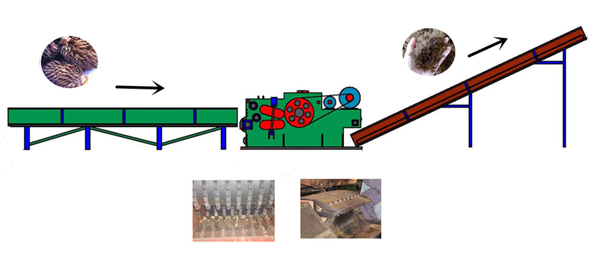

** EFB CHIPPER

As the most efficient primary EFB size machine, EFB chipper only consumes less than 10KW electricity for 1Ton

production. EFB or oil palm long fibers both can be well cut into short fiber in Length 10-35mm. Which is a good size

for the dryer to process.

※Technical Parameter

|

Model

|

Motor |

Capacity T/H |

Machine Dimension mm |

Weight |

|

KJDS315D |

45KW |

3-6 |

2700*1800*1450 |

3800kgs |

|

KJDS316D |

55KW |

6-8 |

3100*2000*1500 |

4680kgs |

|

KJDS318D |

110-132KW |

10-15 |

3500*2400*1900 |

8300kgs |

|

||||

How does the EFB chipper work? Please click the VIDEO

**EFB Fiber Dryer

To make good quality EFB pellets, the fibers must be at a moisture level of around 15%. Too high or too low moisture will

lead to failure of pelleting. Thus the rotary drum dryer is used.

|

The drying system is made of fiber feeding, drying chamber, fiber discharging, and stove.

**EFB Fine Fiber Miller / EFB Crusher

|

Special Features of PALM EFB fine fiber miller:

| a)· The rotor knives(flying knives) are designed with SHEARING CUTTING technology. In comparison to the standard full angled knives, the "V" chevron design creates a consistent material cutting concentration toward the middle area of the rotor for ultimate size reduction. The "V" cutting configuration reduced knife wear and eliminates excessive cutting chamber sidewall wear. |

| b)· Enlarged main shaft, diameter 160mm. 40CR steel |

| c)· Speed adjustable feeding conveyor |

| d)· Low rpm of the rotor(20-30rpm), cut the palm EFB fiber evenly |

| e). Output fiber length: 4-6mm, suitable for making pellets |

| f)· Wearable parts |

|

g)· Soft Start for the Malaysian market, SK brand Inverter. China's famous brand electrical appliance CHNT. China famous

brand motor WNM, or brand BEIDE. Bearing made from ZWZ.

|

※Technical Parameter

| Model | KJ-FFM1000 | KJ-FFM1200 |

| Main Motor | 55kw | 90kw |

| Rotor knives(pcs) | 5*2 | 5*2 |

| Stator knives(pcs) | 2*2 | 2*2 |

| Material of knives | 9CrSi | 9CrSi |

| Rotor Width(mm) | 1000 | 1200 |

| Machine Input open(mm) | 1000*830 | 1200*900 |

| Capacity on dried EFB Fiber | 1-1.2TPH | 2TPH or more |

| Dimension(mm) | 3100*1900*1900 | 3500*2100*2100 |

| Weight(kgs) | 3500 | 4500 |

| Machine start type | Soft start or star-delta | Soft start or star-delta |

How does the EFB Fine Fiber Miller work? Please click the VIDEO

**EFB Pellet Mill

|

Vertical Ring die pellet mill is best suitable for making EFB pellets. Because EFB fiber has bad flow, easy to jam.

While fiber drop to the pelletizing chamber by gravity will avoid the jam.

※Technical Parameter

| Model | KJ-VPM560 | KJ-VPM700 |

| Main Motor | 90-110kw | 132-160kw |

| Ring die hole size | 6mm or 8mm | 6mm or 8mm |

| The material of the Ring die | Carbon steel or stainless steel | Carbon steel or stainless steel |

| Capacity on dried EFB Fiber | 0.8-1.5TPH | 2TPH or more |

| Dimension(mm) | 2800*1300*2200 | 2400*1400*1800 |

| Weight(kgs) | 5000 | 7000 |

| Machine start type | Soft start or star-delta | Soft start or star-delta |